Have you been thinking about upgrading your printing quality with an addition of UV flatbed Printer to your current printing business? Are you somewhat confused with creating the ideal choice between the roll to roll and flatbed UV printer ? How can you decide on the one which’s not just appropriate for your organization now, but appropriate for you in the long run as your company grows ? You have come to the ideal location. This guide can allow you to make sense of the intricacies of UV flatbed printing technologies. Whether you are into printing business and your printer produces large format digital prints or you are searching to add UV LED flatbed machine to your current quick-print, offset, screen printing, packaging, the objective of this article is to help you realize the options you have and what to look for when choosing a UV flatbed printer.

There are basically 2 categories; Roll to Roll or Moving Media and True Flatbed printing

Moving Media/ Roll to Roll Printing

Back to back printing with accurate dot placement solution and low ink consumption makes it a perfect solution for indoor and outdoor applications. The media whether flex, vinyl, PET, Wallpaper moves ensuring unprecedented print speed and high-quality.

True Flatbed

In True flatbed printing technology, the media is held on a table with a maximum size of 8by4 feet possible and the printing system moves over the media.

Roll to Roll UV printer benefits:

• Reduced capital expenditure, as the Printer requires just altered media handling accessory or capabilities tables to permit feeding.

• Hybrid printers provide stores a 2-for-1: the capability to also print on roll-based media with the exact same printer.

Moving-media printer drawbacks:

• Transferring the media can result in skewing of the picture, requiring a reprint and leading to unrecoverable material and time and wastage of money.

• This printer structure Typically utilizes pinch roller or belt-drive systems which could leave marks on the print, plus they frequently need cleaning of the drive between prints to get rid of excess ink.

• Useful majorly on lightweight media which have a minumum of one 90-degree angle, as a corner must begin feeding the stiff media through the printer. They do bad print on irregularly-shaped or even non-square objects (unless an extra custom made jig is used to maintain all of the bits set up as they proceed through the printer), on thick substrates, or substances that have an irregular surface like plywood or stained canvas.

• This structure lacks the geometry necessary to tile big images over several planks, which can be a frequent program for exhibition graphics manufacturers

• Even Though the printer footprint can be modest, the working place”footprint” is relatively large, requiring space on the two feed and exit sides of this printer.

• Requires additional operator Intervention whilst printing to make sure boards don’t skew or miss-feed.

• Changing between roll-based and rigid-based printing needs physically reconfiguring the machine.

True flatbed

Comparable to screen printing, the True flatbed layout keeps media stationary on a desk and moves the printing system over the media. Vacuum tables are frequently utilized in true flatbed design, helping to ensure there is not any unintended media motion during printing.

True flatbed printer benefits:

• The printing quality is optimized since only the printer is shifting while the media is kept stationary against a desk. This maximizes productivity by supplying perfect and repeatable bi-directional orientation as well as the bodily registration (press to picture ) is optimized leading to the greatest possible quality pictures. That is even more peculiar when exotic piezoelectric printing technology – like grayscale printing heads – are utilized.

• along with some stiff media, the true flatbed structure enables any reasonably level object to be printed upon, providing the capacity to generate many exotic and unconventional applications.

• The true flatbed architecture Printing to prefinished pieces may save money and time by eliminating the requirement to print “overs” to cover the possible harm to a printed item at the finishing phase.

• Multiple boards may be printed Simultaneously simply by putting them onto the flatbed. This is beneficial for smaller sized substances, such as directional signs which are published in volume.

• Double-sided prints may easily Be printed in excellent quality.

• Large screens tiled (over Several boards) may be printed in excellent alignment so that when assembled, there aren’t any discernable gaps brought on by image/media skewing.

• The capability to publish on Irregularly-shaped or non-square objects, heavy substrates, remarkably smooth media like glass, or substances that have an irregular surface like plywood.

• The capability to print on thick

Roll media choice can easily change between roll-based to stiff printing. Additionally, this can boost productivity as the stiff substrate can be pre-loaded on the vacuum during roll-based printing.

True flatbed printer drawbacks:

• Initial funding costs can be Higher than hybrids.

• Roll printing capacity Isn’t Built-into the machine requiring an optional setup.

Conclusion

Your decision on whether to buy a hybrid-style machine or true flatbed UV printer should be driven by the capacity for generating as much revenue as possible in the Single printer, tempered from the actual area you’ve got or is able to add. Make Sure You ask manufacturers for real world ROI models which reflect your company considerations.

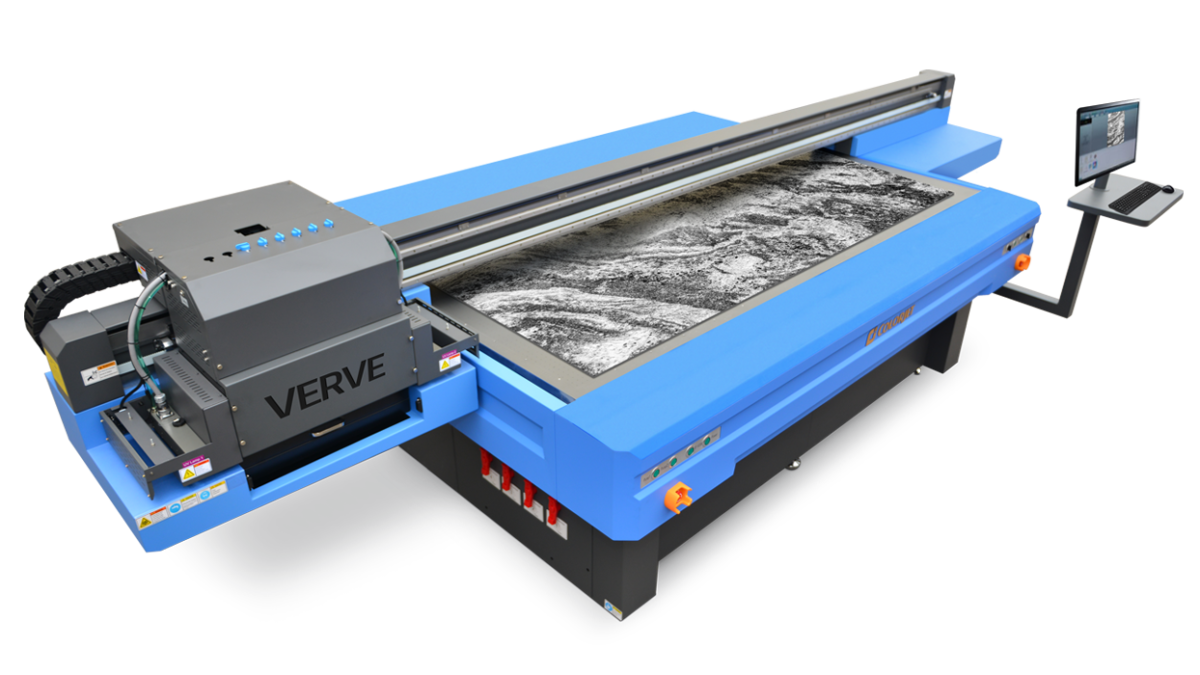

With Colorjet, you get both the options available. Vulcan is High Speed Roll to Roll UV LED Inkjet Printer, while Verve LED is a true UV LED Flatbed Printer. As discussed above, roll to roll printer is most effective in printing applications like Banners, Floor Standee, Billboard, Wall Graphics, Window Displays, Signage, etc. where the media if flat and flexible. Whereas, Verve is highly beneficial for printing on rigid applications like glass, wood, metal, acrylic or any other rigid surface with maximum possible height and width of media possible is 8 feet by 4 feet.

Related posts

Subscribe Now

* You will receive the latest news and updates on your favorite celebrities!

Meet the Author

Gillion is a multi-concept WordPress theme that lets you create blog, magazine, news, review websites. With clean and functional design and lots of useful features theme will deliver amazing user experience to your clients and readers.

Learn moreCategories

- Animals (6)

- Business (579)

- Cooking (3)

- Design (17)

- Education (59)

- Entertainment (62)

- Fashion (39)

- FASHION (89)

- Featured (19)

- FOOD (42)

- Guide (55)

- Health (290)

- HOME (184)

- Interior (14)

- Life (8)

- Lifestyle (111)

- Motivation (6)

- News (47)

- People (4)

- Photography (5)

- Review (4)

- Style (4)

- TECH (176)

- Travel (107)

- Uncategorized (1,441)

Stay connected